- The Conveyor

- Posts

- Predicting Machine Failures Before They Happen

Predicting Machine Failures Before They Happen

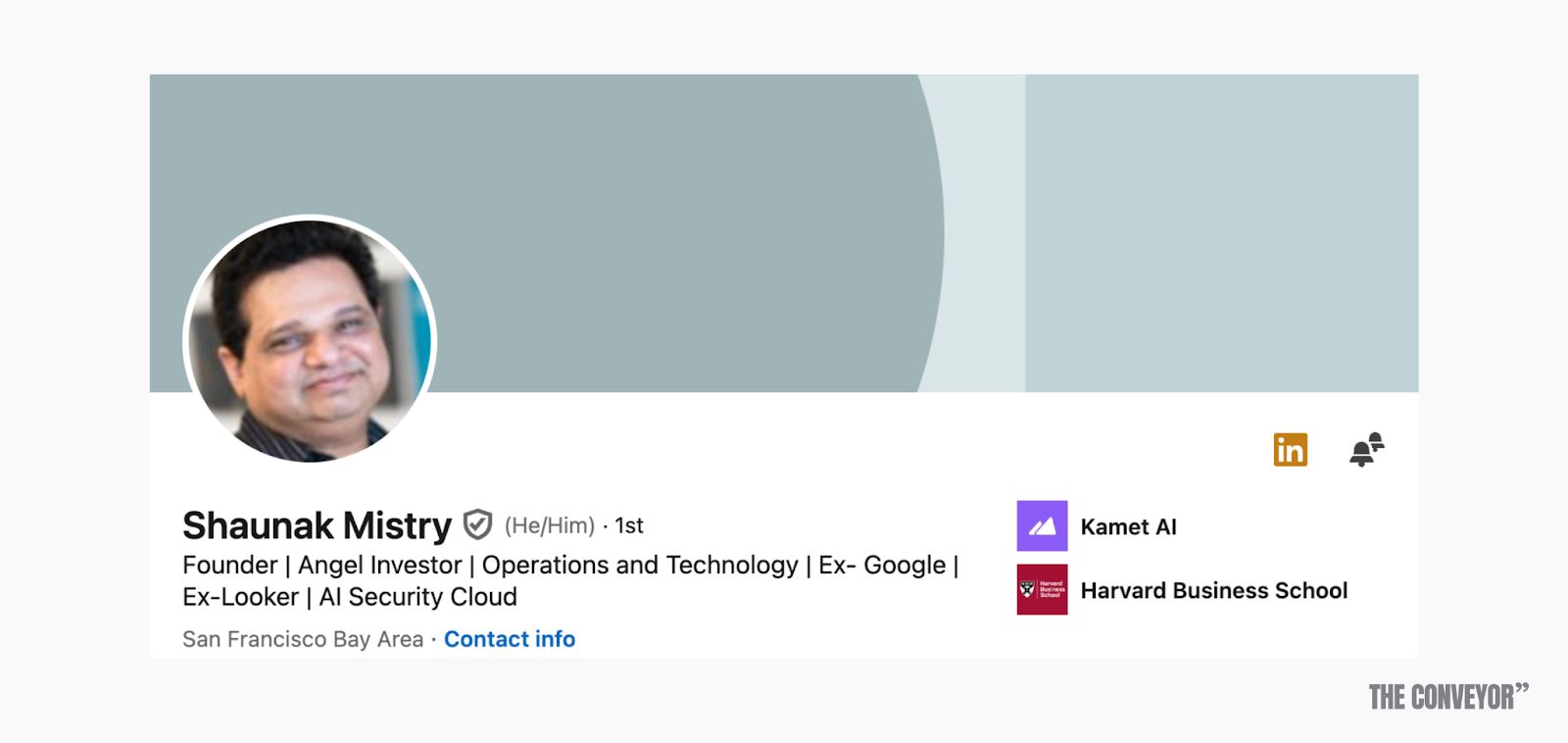

With Kamet AI CTO Shaunak Mistry on fragmented tooling, why mid-sized companies fall behind, and Kamet’s product.

Operational risks can go unnoticed until it’s too late. A machine fails, operations slow down, or downtime eats away at profits.

It’s a problem that’s been around for years, and Kamet AI is on a mission to change that.

Their goal isn’t just about catching issues after they happen - it’s about preventing them altogether and, in turn, improving the business case for robotics and automation.

This Q&A is about how Kamet AI brings predictive analytics to companies that don’t have the resources to build custom tools like the giants, Amazon and Walmart.

By tapping into data from robots, warehouse management systems, and even legacy equipment, Kamet AI offers insights that keep operations running smoothly and downtime in check.

They’ve recently rolled out an early access program and are already working with partners in warehousing, manufacturing, logistics, and mining.

I sat down with Shaunak Mistry, Kamet’s co-founder and CTO, to dive into their journey so far, the product’s core features, and where Kamet AI is headed next.

Table of Contents

This conversation has been edited for length and clarity. If you're short on time, skip to the TL;DR section for the key takeaways.

The rest of this story is for paid subscribers only.

Already a subscriber? Sign in.

Want 12 months free? Connect with me on LinkedIn and I'll give you access.

Reply